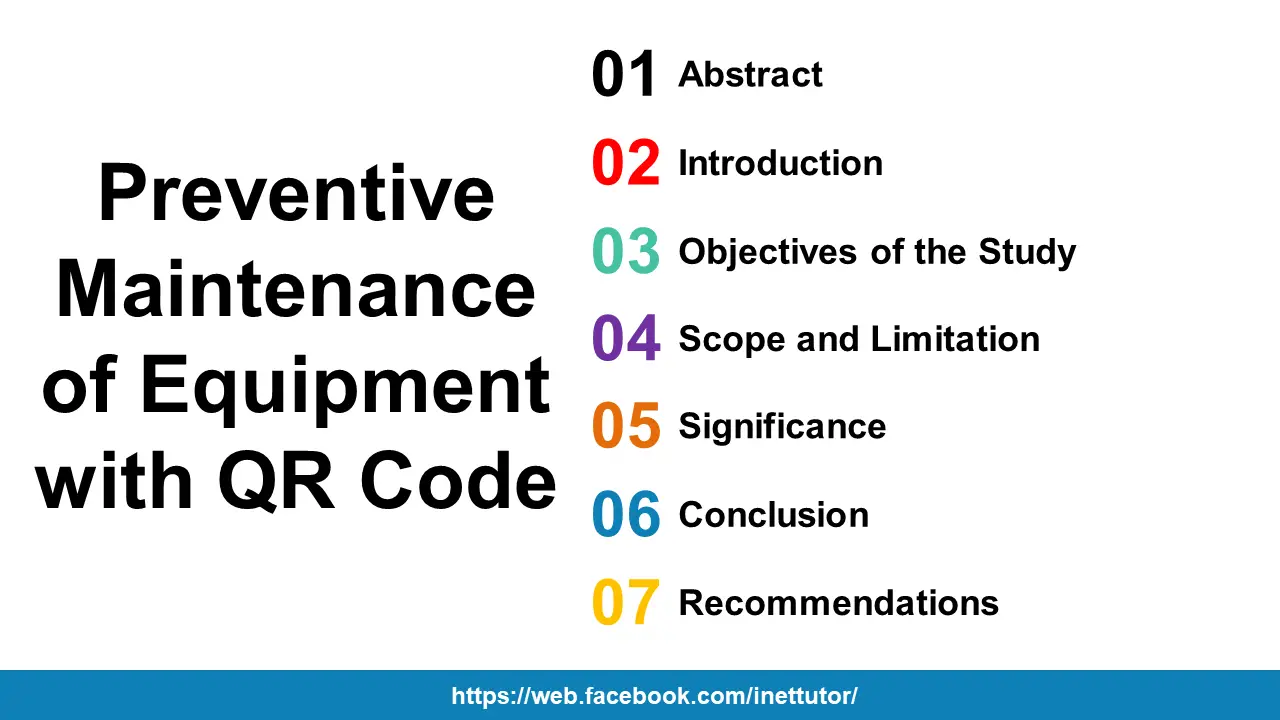

Preventive Maintenance of Equipment with QR Code

Abstract

Table of Contents

Technological innovations significantly contribute to the improvement of every business operation. Businesses employ computerized systems to further improve business efficiency and overall customer experience.

Equipment maintenance is critical to an organization’s ability to save money and boost its financial position. The researchers conducted the study to assess the current method used for equipment maintenance in businesses. After a thorough study and investigation, the researchers have found out that the current method of tracking equipment maintenance is inefficient and ineffective.

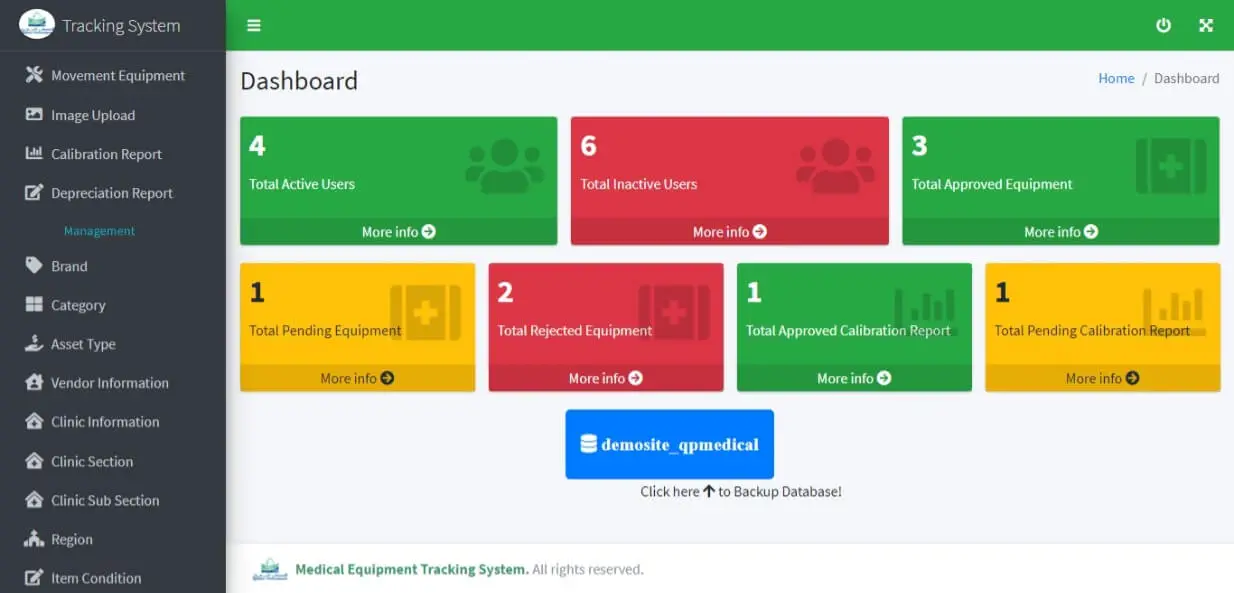

The capstone project, “Preventive Maintenance of Equipment with QR Code” is QR-code-based preventive maintenance for equipment. Different pieces of equipment will have specific QR codes that, when scanned, will provide information and allow users to keep track of the equipment’s status. It is an automated system designed to ensure that equipment does not break or wear out unpredictably.

The implementation of the system is deemed beneficial for companies that heavily rely on machines or equipment for their business operations. The system’s main purpose is to track the status and condition of the equipment by scanning the QR-code assigned to each component. The proposed project will resolve all issues and difficulties that existed in the previous system for inspecting the condition of equipment and ensuring that it is properly maintained and functioning.

The development of the Preventive Maintenance of Equipment with a QR Code System will improve the business efficiency of companies. The said project will allow preventive maintenance of equipment easy, fast, accurate and convenient.

Introduction of the Study

The capstone project, “Preventive Maintenance of Equipment with QR Code” is intended for companies or organizations that rely on equipment as their biggest investment. The application helps extend the useful life of that equipment and ensures that the equipment does not break or wear out unpredictably.

Equipment maintenance is critical to an organization’s ability to save money and boost its financial position. Keeping track of maintenance for each piece of equipment in an organization can be time-consuming, particularly if the company uses paper records. Using the manual method, companies may encounter difficulties in keeping a grasp of information needed for maintenance tracking. Organizations need an effective tool in making maintenance tracking feasible and easy.

To address the aforementioned problems, the researchers of the study proposed a Preventive Maintenance of Equipment with QR Code. The software would automate the processes for monitoring equipment maintenance. Different pieces of equipment will have specific QR codes that, when scanned, will provide information and allow users to keep track of the equipment’s status. Preventative maintenance reduces the risk of unpredictable breakdowns, which can cause business disruption by preventing required equipment from being unavailable.

Objectives of the Study

General Objective – The project’s main goal is to design and develop a Preventive Maintenance of Equipment with QR Code that will help businesses keep track of equipment maintenance and extend the life of their most valuable assets.

The following are the specific objectives of the project:

- To develop a tool to effectively track and monitor the maintenance of equipment.

- The system will provide up-to-the-minute, detailed information concerning equipment maintenance

- The system will help inventory managers identify trends in maintenance, such as problem equipment or over or under-utilization of certain assets.

- To develop a technology-assisted tool that will eliminate inaccuracies in equipment tracking.

- The system will reduce errors in maintenance.

Scope of the Study

The researchers will develop a QR code-based system that stores details of the equipment’s condition and status for monitoring. The project mainly focuses on designing and developing a system that caters to the tracking and monitoring of equipment. The system will ensure that the equipment will not break or wear out unexpectedly that will affect business operations. The researchers will choose companies or organizations as respondents to the study.

Significance of the Study

The following individuals or groups will benefit from the success of the project:

Companies/Organization. The system will ensure that the company would not suffer from losses cause by the sudden unavailability of equipment. It will help companies reduce costs in maintaining equipment.

Maintenance Department. The program will ease up their job in pulling up the information needed in tracking and monitoring equipment maintenance.

Researchers. The success of the study will help researchers harness their skills in developing helpful programs for organizations and companies.

Future Researchers. The study will serve as their basis in pursuing the same project or developing their version of the project.

Conclusion

Equipment is considered as the biggest investment of companies. Businesses heavily rely on their machinery to operate their business. Thus, it is important to ensure that the equipment is well maintained. The researchers developed a system that will automate the process of preventive maintenance of equipment. The result of the study showed that the developed system provides the needs and requirements of the intended user to efficiently monitor and maintain the good condition of the equipment.

Therefore, the researchers concluded that the developed preventive maintenance system is an effective tool to ensure that the equipment will not malfunction unexpectedly. The system will ensure that the machines will continue to operate without causing the businesses unexpected problems. It will be easier for the maintenance staff to capture the status and condition of the equipment by using the QR-code-based system.

Recommendations

The researchers strongly recommend the implementation of the system in businesses that rely largely on machinery to run their operations. The designed system comes highly recommended because of its efficiency and dependability. Monitoring and maintaining a company’s equipment can save time and money. The researchers also suggest that the intended users should have enough knowledge about the features and how the system works to correctly utilize them.

The following is a list of suggestions made by the researchers:

- The experts strongly suggest that firms use the technology to conveniently monitor and maintain their equipment.

- The company’s maintenance staff should install and use a QR-code-based system to monitor and maintain each piece of equipment effectively and conveniently.

- The developed system is highly recommended for it will make preventive maintenance of equipment easy, convenient, and reliable.

You may visit our Facebook page for more information, inquiries, and comments.

Hire our team to do the project.